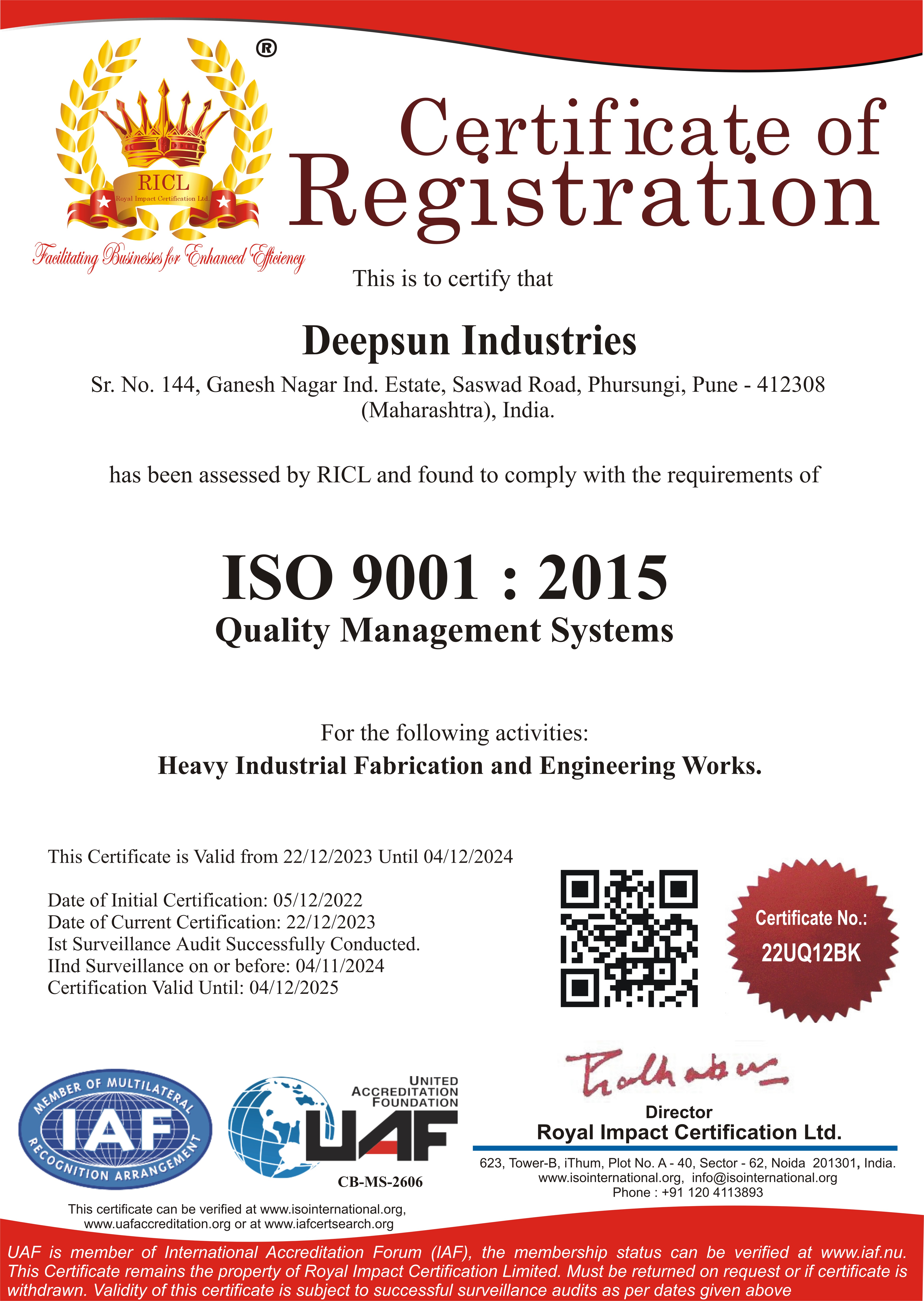

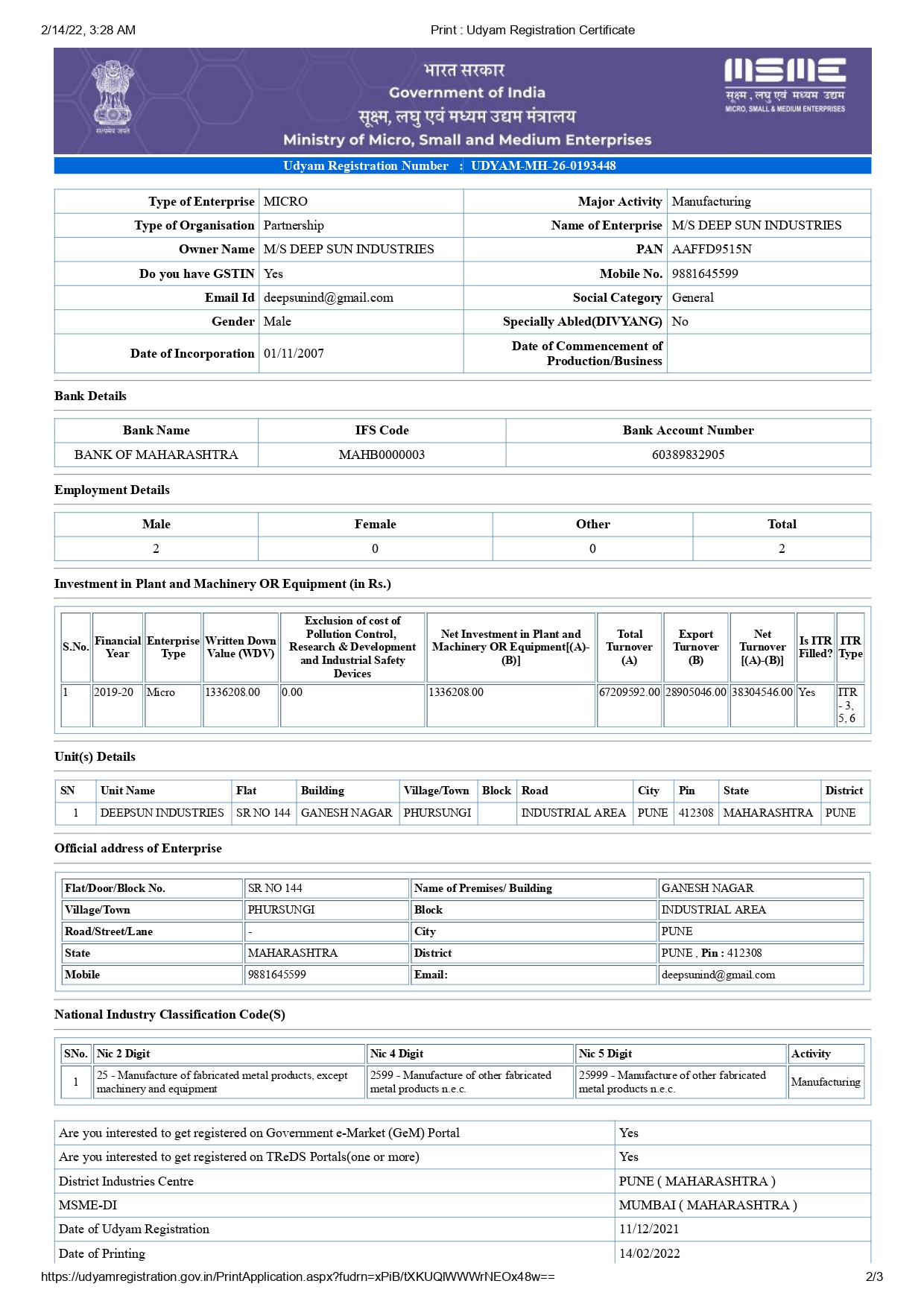

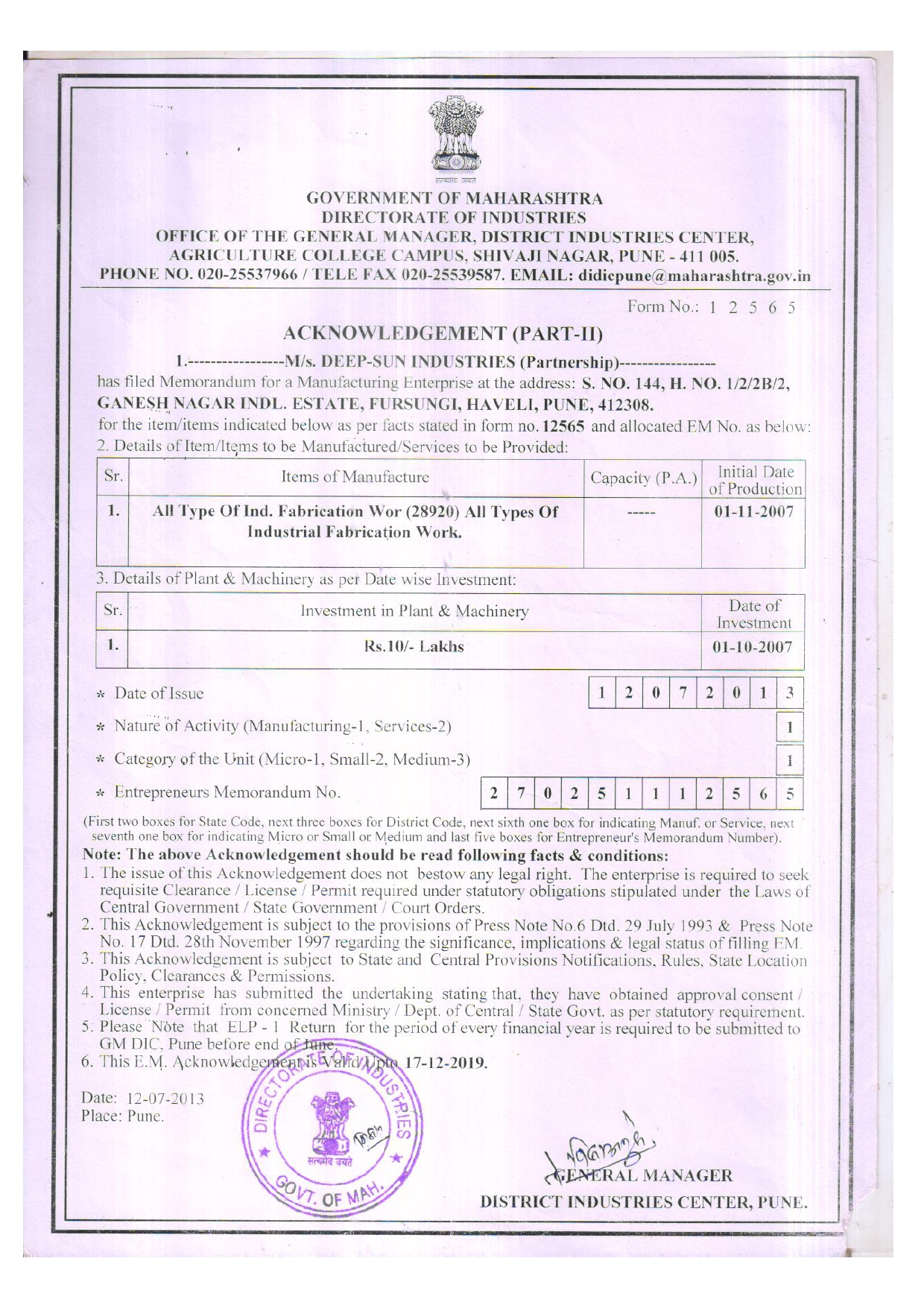

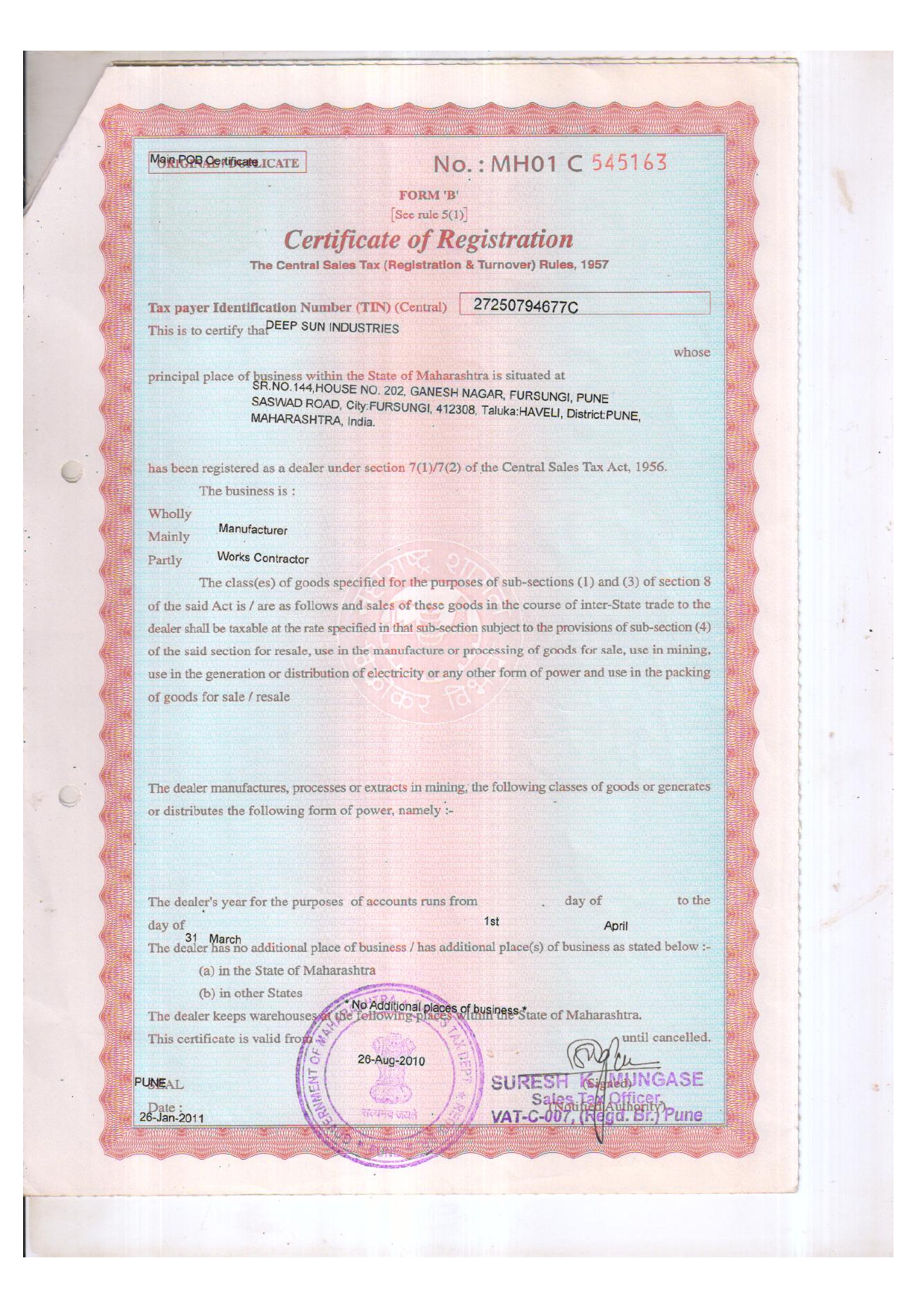

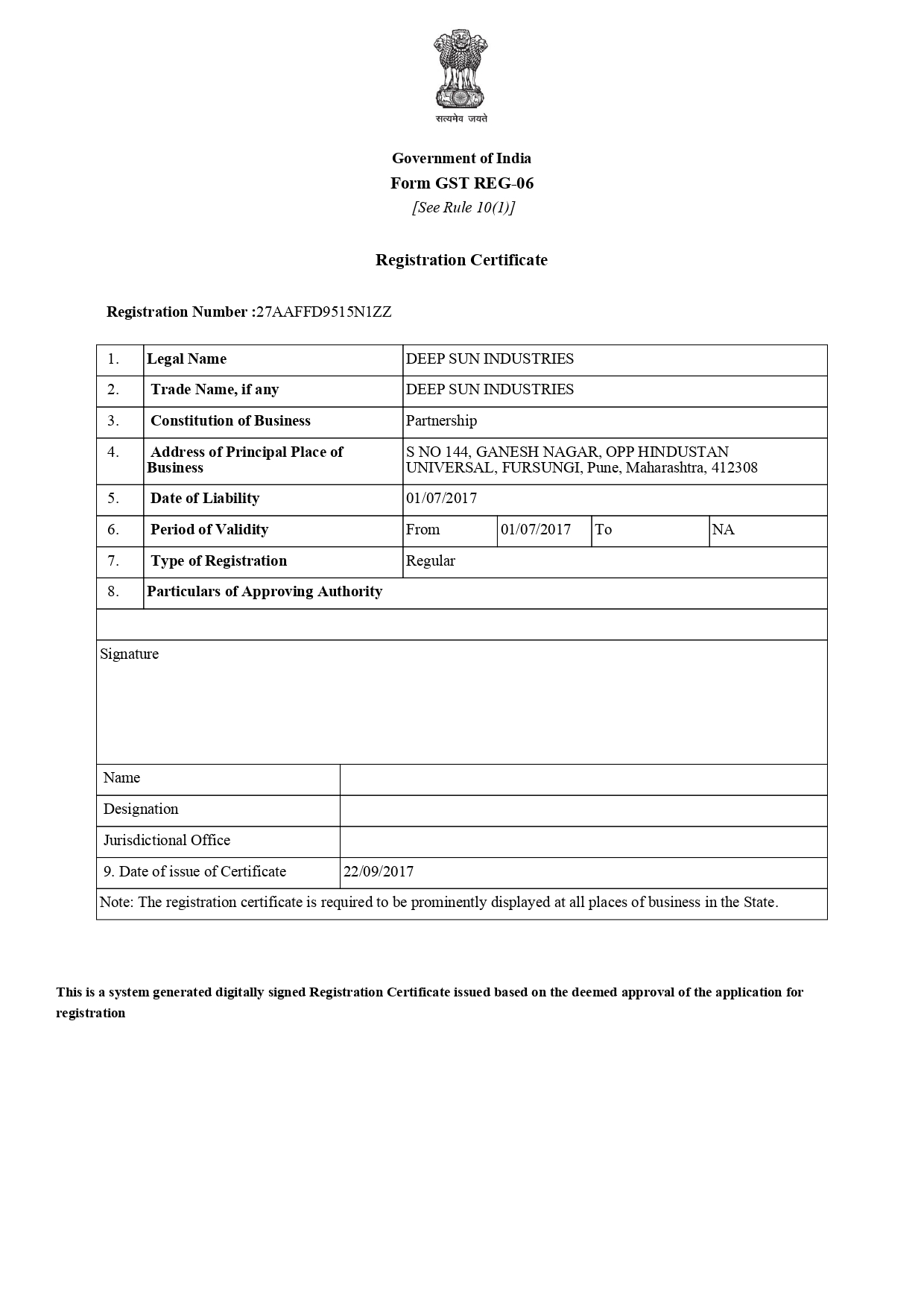

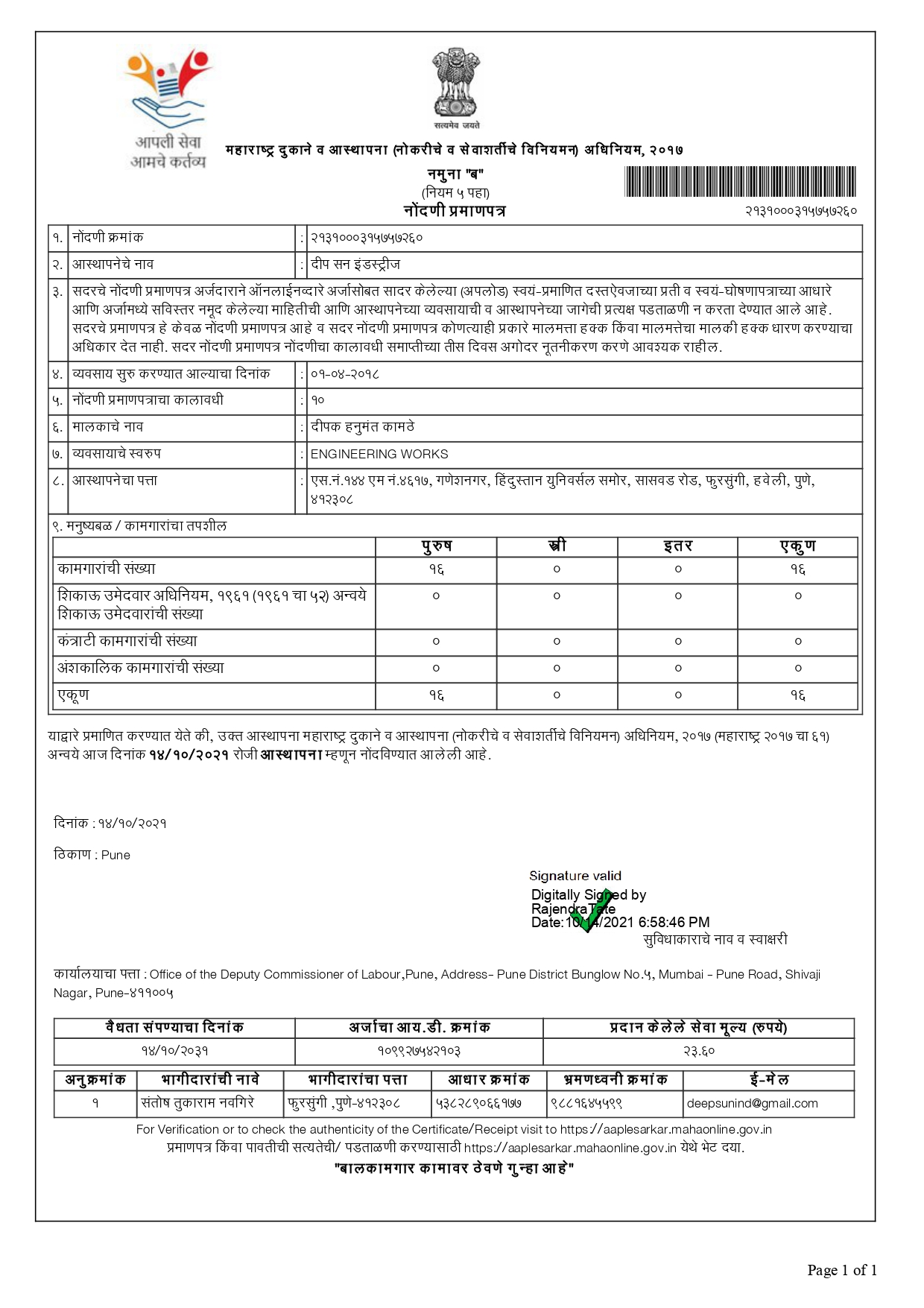

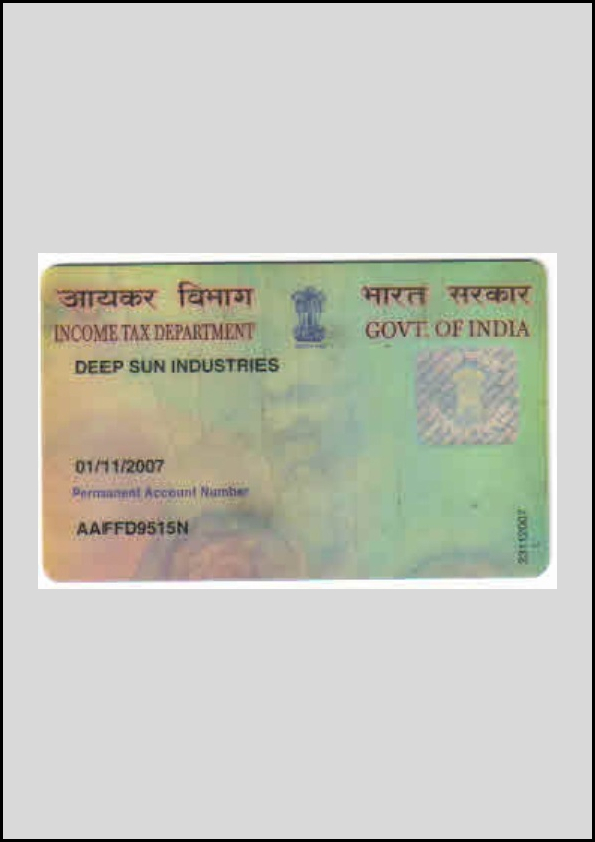

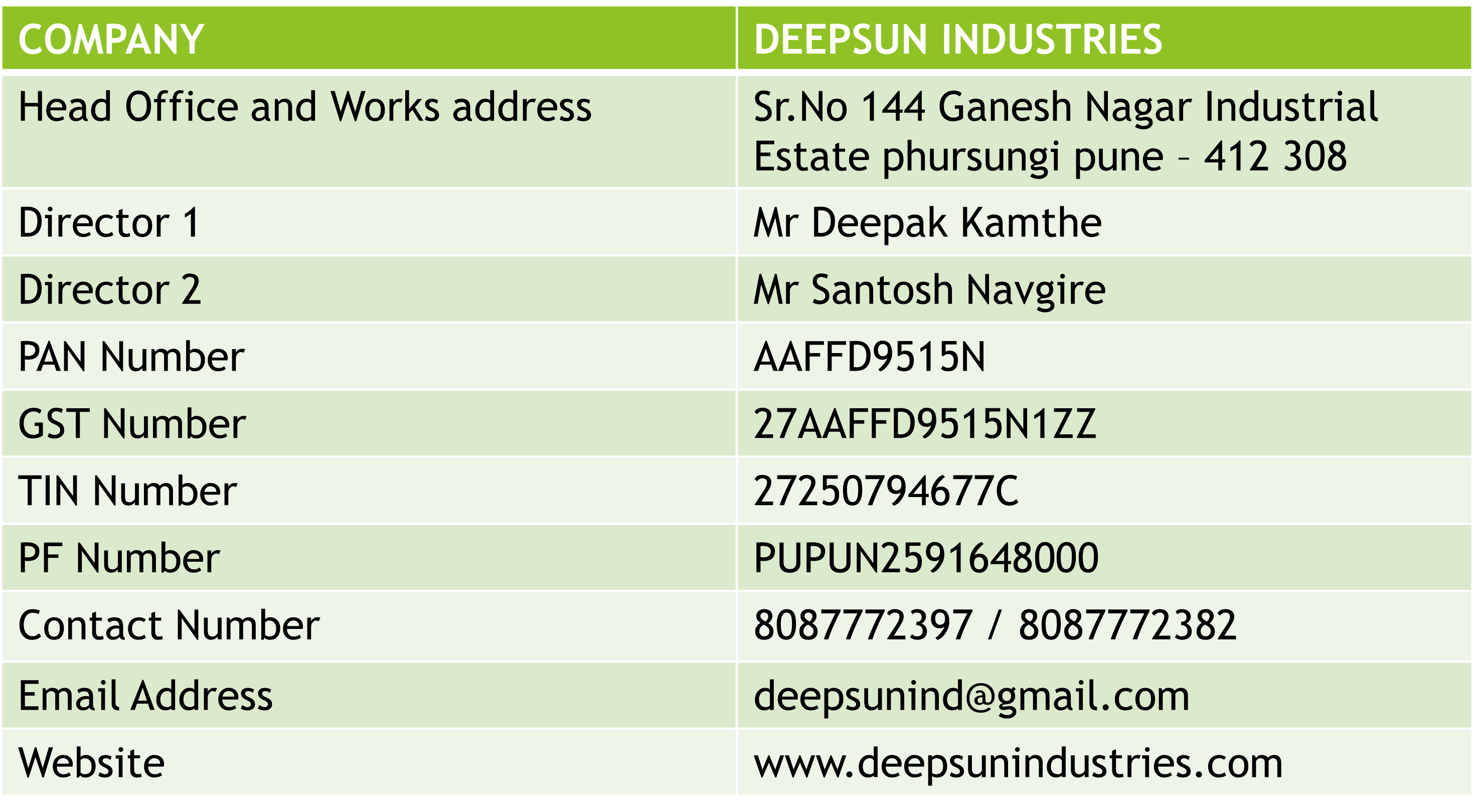

Deepsun Industries is founded by two young minds Mr. Santosh Navgire & Mr. Deepak Kamthe , in 2008. The company is engaged in the heavy fabrication work and served to many Large , Medium and small case companies.

Company Profile

In year 2012, Deepsun Industries started working on project of reputed machine building OEM – Electronica Plastic Machine Ltd. We got the large order of injection molding Machine Base Frames. This association is healthier on the basis of quality and timely delivery. We are supplying the machine base frames till today.

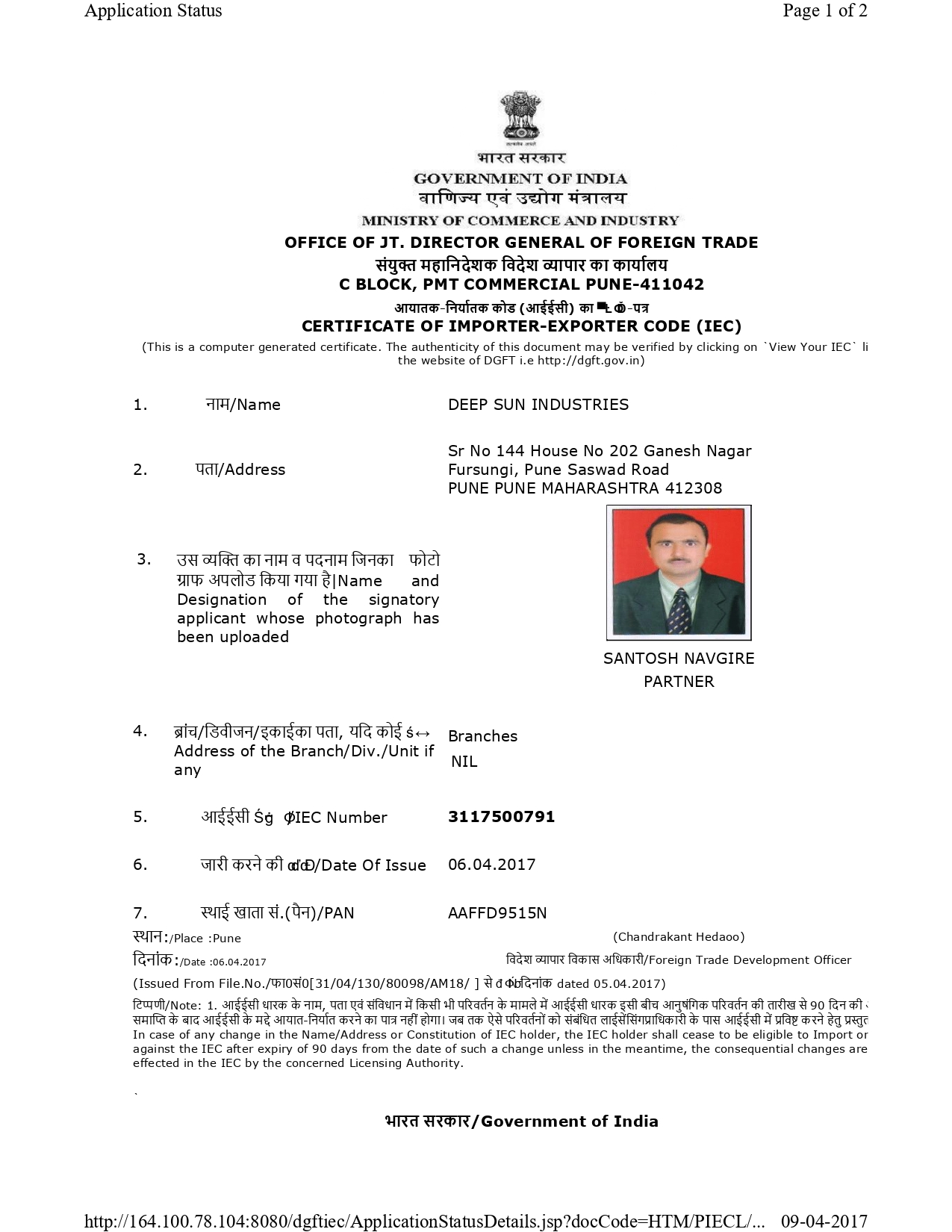

Entry in Export orders:- Deepsun Industries bagged 1st Export order from M/s Loadstar Quality LLC in 2016. It was a challenging job of Complete storage box of 16Ft X 7Ft, SS composite sheets.

In 2021 Deepsun Industries sucessfullay completed the Thermal Oxidizer (RTO) 9Mtr X 2.5Mtr X 6Mtr (Height) for M/s Yantric Engineering. We also successfully completed IBR- DE- Aveator Tank S.S. Pressure vessal , Reactor and Heat Exchanger.

In 2022, Deepsun Industries added one more sector for diversification, that was wind mill engery. The remarkable order from M/s Suzlon Engery Limited contain various wind mill parts like fabricated structure and platforms are supplied.

Deepsun Industries worked for M/s ASARA Equipments for Electric Belt freight loader weldment frames, Pallet Dolley frames

Deepsun Industries developed expertise in Water tank fabrication and completed project of 90,000 Lit capacity tank for Bajaj Power Equipments.

From 2023 Deepsun Industries are expanding wings in PEB structure and Storage racks for Industrial storage solution and Consumer display racks for Malls and various showrooms.